The Federal Republic of Germany has decided to supply the Gepard anti-aircraft tank to the Ukrainian armed forces. Delays in the availability of agents for this system are said to have delayed operational readiness. The corona pandemic has disrupted sensitive global supply chains. An accident in the Suez Canal led to a week-long shutdown of one of the world's most important waterways. All of this succinctly shows how important redundant supply chains are. For armed forces, this requirement is even more pronounced and the trend towards warehousing with goods only available on a just-in-time basis is unsatisfactory for the national and alliance defense scenario. The Latin proverb “si vis pacem, para bellum” is groundbreaking in this regard. However, a complete shift away from demand-based replenishment is not to be expected and would also nullify the advantages gained as a result. FUJITSU's logistics solutions in the defense environment therefore rely on a hybrid model in which all aspects of the military logistics chain are taken into account. This is done, among other things, with edgeware-supported asset tracking.

What does that mean?

Edgeware refers to an immediate evaluation of information close to sensors. Asset tracking is used to determine location and quantities. In addition to the logistics goods, supply chain transshipment points, storage hubs, route availability for transport routes or the delivery ability of suppliers are also tracked. The type of information and which sensors it is collected through is flexible and builds on existing infrastructures. Whether databases, CCTV traffic cameras, optronic satellite images, GPS data or pressure sensors on truck loading docks - the possibilities for collecting data are almost endless. The challenge, as is so often the case, is to make the information usable so that it relieves the burden on the end user and the military leadership recognizes problems at an early stage. To achieve this, scalability is important in order to channel the flood of data and provide everyone involved with only the information they need. A sensitive approach almost automatically leads to increased data security.

FUJITSU's hybrid approach goes by the name GlobeRanger and combines existing information with individual requirements for the logistics goods. In this way, durability cycles or information about wear intervals can be recorded and thus monitored. This technology has already become established in use by NATO forces such as the US Army and the Royal Army and is used in the following areas, among others:

Personnel registration and weapons inventory

Yes, soldiers and handguns can also be tracked using Edgeware technology. This chain begins with the acquisition of weapons and ammunition and ends with the tracking of ammunition stocks at battalion, company or platoon level. In the real world, this information enables a crucial component of a real-time situation picture and order planning. The leadership knows immediately who has what skills and where the operational component is located.

Monitoring of weather influences on active agents

By monitoring environmental data, conclusions can be drawn about the operational readiness of the ammunition if it is exposed to environmental influences during storage or transport. This data corresponds to the real image and often differs significantly from the manufacturer's laboratory data. The result is more advanced, condition-dependent or even preventative maintenance predictions that are possible with the data obtained in this way. The use of edgeware technology makes it possible to store environmental data with predefined limit values and passive sensors. Based on this, it can be determined whether ammunition was exposed to major fluctuations in temperature or humidity and whether this could have influenced the period of use.

Saving time in daily work

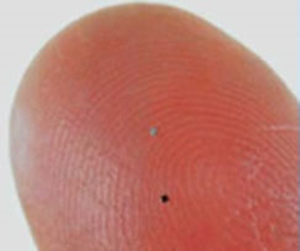

Wenn wir uns vor Augen führen, wieviel Material sich auf einzelnen Fahrzeugen wie einem Schützenpanzer befindet, können wir darüber nur Mutmaßungen aufstellen, wieviel Zeit die Besatzung bei der Fahrzeugübernahme, dem Betrieb und der Abgabe verbraucht, um die Vollzähligkeit der Ausrüstung zu prüfen. Diese Zeit fehlt im Einsatz und Übungsbetrieb gleichermaßen. Der Schraubenschlüssel, der es nach dem letzten Einsatz nicht mehr in die Ausstattung geschafft hat, der Wasser- oder Treibstoffkanister, der undicht geworden ist, bis hin zu den Tarnnetzgestängen. Die gesamte Ausrüstung auf dem obenstehenden Bild kann mittels Asset Tracking geortet werden. Die Funktionsweise ist einfach, funktional und baut nicht, wie vielleicht erwartet, auf eine Netzwerkstruktur oder ein WLAN-Netz im MARDER auf, sondern setzt auf kostengünstige RFID-Tags. GlobeRanger nutzt RFID-Tags als passive oder aktive Sensoren, die ohne Stromversorgung funktionieren und auch in Uniformen verarbeitet werden können. Neben dem Standort eines logistischen Stückgutes können auch Datensätze hinterlegt werden, z. B. wann die Uniform produziert wurde und wann ein Austausch zu erfolgen hat. Die Einsätze sind vielfältig und die gewonnen Daten bilden die notwendige Grundlage für weitere Digitalisierungsprojekte wie z. B. Digital Twins. In den Bereichen Verteidigung und nationale Sicherheit des US-Verteidigungsministeriums, DoE, Homeland Security, DLA und in allen Teilstreitkräften der US-Army umfassen die Anwendungsfelder:

- Logistics and supply chain monitoring

- Personnel and ammunition monitoring in security operations

- personalized armory management (using biosensor access control and weapons issuance)

- Inventory management of general cargo

- Monitoring shipping and receiving processes.

For more information, seehttps://www.fujitsu.com/de/solutions/industry/defence/.