Due to the special penetration mechanism (hydrodynamic penetration), shaped charges are very effective against all known armor materials, almost regardless of the hardness of the target material. Reactive protection is a suitable answer here.

The challenge

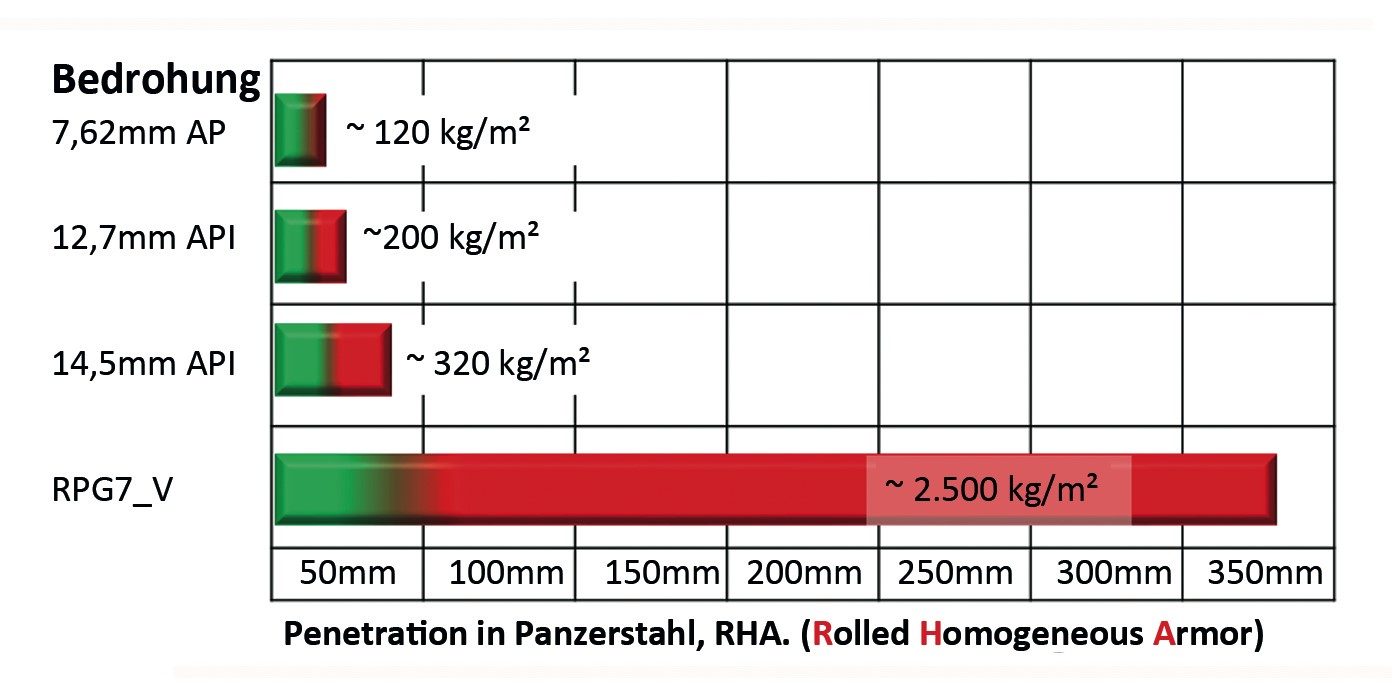

In order to be safe against such threats, one quickly reaches significant weights of armor. Even in the case of the widespread charge of the warhead of the RPG 7 V, with an underlying penetration depth of approx. 320 mm in steel, more than 2.5 tons would be required for each square meter of area to be protected. On the other hand, there is the requirement that the infantry fighting vehicle (IFV) Puma should have all-round effective protection against shaped charges and a large number of other threats. Even the use of special armor materials with high effectiveness against shaped charges at low densities does not lead to the necessary weight reductions of the system. The achievable weight saving is then around 50 percent.

The use of so-called statistical protection measures such as nets or slat armor were also not suitable overall against the background of the protection requirements.

Reactive protection for the AFV Puma against shaped charge threats

Design and operation

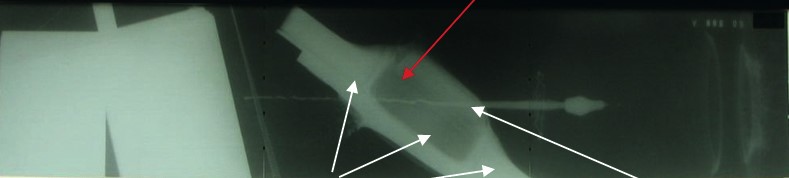

Reactive protection (ERA, Explosive Reactive Armour) as such is based on the work of Professor Manfred Held and has been known for a long time. The basic structure is very simple: A layer of explosives is attached between two plates (made of metal or composite material), this so-called sandwich or "active element" is aligned at an angle to the direction of incidence of the threat. An impacting shaped charge jet triggers the explosive, which then accelerates the plates at an angle against the jet. The jet always finds new material to penetrate, and the blast of the explosive has a massive disruptive effect on the incoming jet particles. This mechanism leads to a drastic reduction in penetration depth. The function is shown in the picture on the left.

How reactive protection works in practice

In the two X-ray flash images, which were taken at different times after initiation, one can see the attacking shaped charge jet and the resulting massive disruption from the plates and the blast. The dangerous, fast parts of the jet at the tip are massively disturbed, massive remains of the jet are rendered harmless by backing plates, as is the blast of the shaped charge and the protective arrangement in order to minimize repercussions on the vehicle. The overall size of the structure and also the amount of explosives depends on the performance of the threat to be combated.

In practice, reactive protection elements are used in closed boxes, the so-called boxes or modules. They contain a certain number of active elements in a suitable arrangement, and their weight is such that they can be easily assembled, disassembled or replaced by the crew of the vehicle if necessary.

At Dynamit Nobel Defense GmbH in Burbach, reactive protection has been developed, tested and tried out for more than ten years. This is often done together with vehicle manufacturers and users, also under the aspect of system compatibility. The first qualifications for vehicles of the Bundeswehr took place on the Marder armored personnel carrier and on the Fennek from Krauss-Maffei Wegmann. The knowledge gained there formed the basis for the development and qualification of the reactive protection for the IFV Puma.

weight balance

The weight of protection systems is described by the so-called "area weight". This is the weight that a protective structure of a given thickness per one m2area weighs. This is illustrated in the image below in a comparison of the thicknesses of steel plates required to protect against the threats listed and the resulting basis weights.

When using reactive protection one can assume that one achieves a weight saving of 80 percent compared to armor steel, including the so-called "parasitic weights" e.g. B. for attachments etc.

safety aspects

When using reactive protection on the IFV Puma, there are significant amounts of explosives on the outer wall. This requires special considerations of safety and system compatibility, ie compatibility with all environmental loads applicable to the vehicle. Only extremely insensitive explosives are used for reactive protection, which only detonate when hit by a shaped charge jet and otherwise remain passive, even when fired on with automatic cannons and powerful KE ammunition. The insensitive explosive used ensures that no sympathetic detonation occurs when a shaped charge jet has hit an active element. Only active elements directly hit by the shaped charge jet detonate, but not adjacent ones.

In addition to these tests, reactive protection modules were flamed with welding torches, exposed to hot exhaust gases, processed with cutting discs, and driven over with heavy chain equipment to prove that none of these stresses is capable of causing an unwanted detonation. The robustness of the system to the stresses of driving as well as the safety have been successfully proven by such tests, which were carried out officially.

In Germany, people were skeptical about reactive protection for a long time, mainly because they feared collateral damage. Normally, metals and metal screws are used as plates in the explosive sandwich, which lead to a considerable amount of splinters and can injure and kill people at relatively long distances (several 100 m). These concerns were allayed by the use of composite panels and plastic screws which, once the explosives had been deployed, disintegrated in the immediate vicinity of the vehicle being fired and did not produce rapid and dangerous fragments. The quantity of explosives, which is also used by the attacking warhead, has been proven to only lead to far below critical loads on the vehicle and the crew.

The protection has not only been extensively tested on test benches, but also when driving in hot climates (Abu Dhabi) and cold climates (winter testing in Norway).

The reactive protection can be used without restriction in all climate areas that also apply to the vehicle. The reactive protection was classified as 1.4 S for transport and storage.

Future viability of reactive protection

The qualified reactive protection for the AFV Puma is deliberately designed in such a way that it only reacts to shaped charge jets. However, by choosing more sensitive explosives and by multiple arrangements, the protection can be designed in such a way that KE projectiles (e.g. from 120 mm cannons) can also be neutralized or their performance can be significantly reduced. Reactive protection concepts from Russia, for example, show that this is possible. Defense against tandem charges is also possible, for example from hand-held anti-tank weapons or shaped-charge warheads fired as guided missiles. This is currently the subject of development work at Dynamit Nobel Defense.

Summary

Reactive protection has been in use on vehicles in many nations for a long time. In Germany, it was only the consistent use of plastic composite materials and the use of a special, very insensitive explosive that led to acceptance.

The reactive protection of the SPz Puma offers many advantages in terms of the required weight, handling and safe function in the defense against shaped charges. The latter if only because only the event "shaped charge bombardment" triggers the mechanism of action. In addition, the protection is extremely robust against the stresses of operating the vehicles, even in the event of collisions with, for example, trees and obstacles in the terrain.

The qualified reactive protection fits into the overall protection concept of the AFV Puma and also offers potential for increasing performance in order to counter higher threats.

Dynamit Nobel Defense GmbH

Media Contact

Dr. Hermann spot-Allee 8

D-57299 Burbach

Tel .: +49 2736 46 2195

Fax: +49 2736 46 62 195

E-mail: marketing@dn-defence.com

Web: www.dn-defence.com